BMS board

Introduction

The Battery Management System (BMS) is the board responsible for the correct functioning of the battery pack. Thereby, it prevents the battery from operating outside its safe boundaries, while monitoring its state, and reporting meaningful data to the end user.

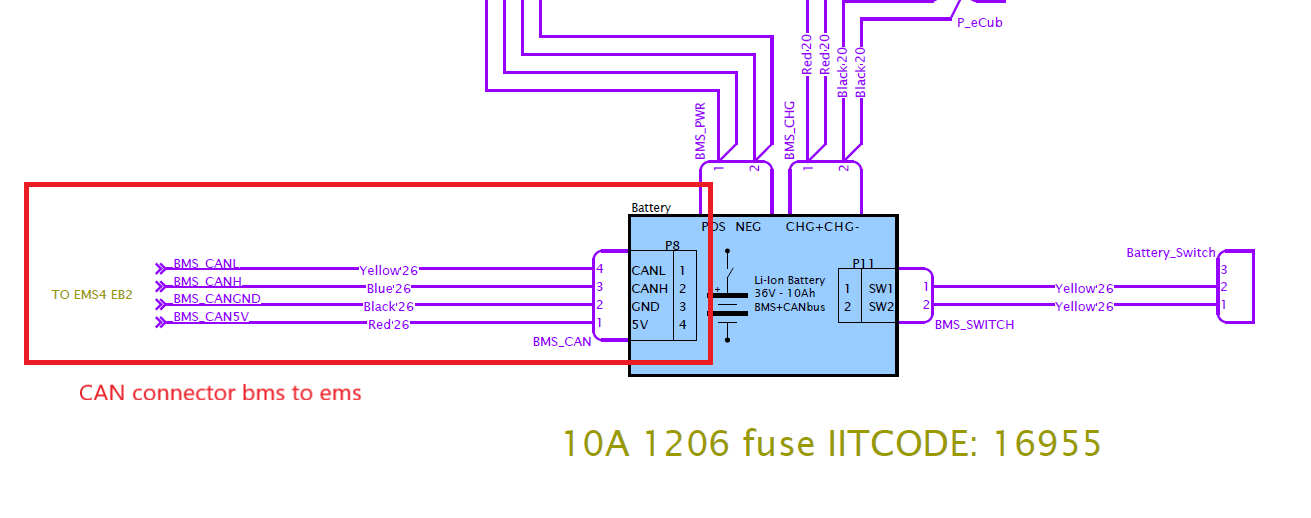

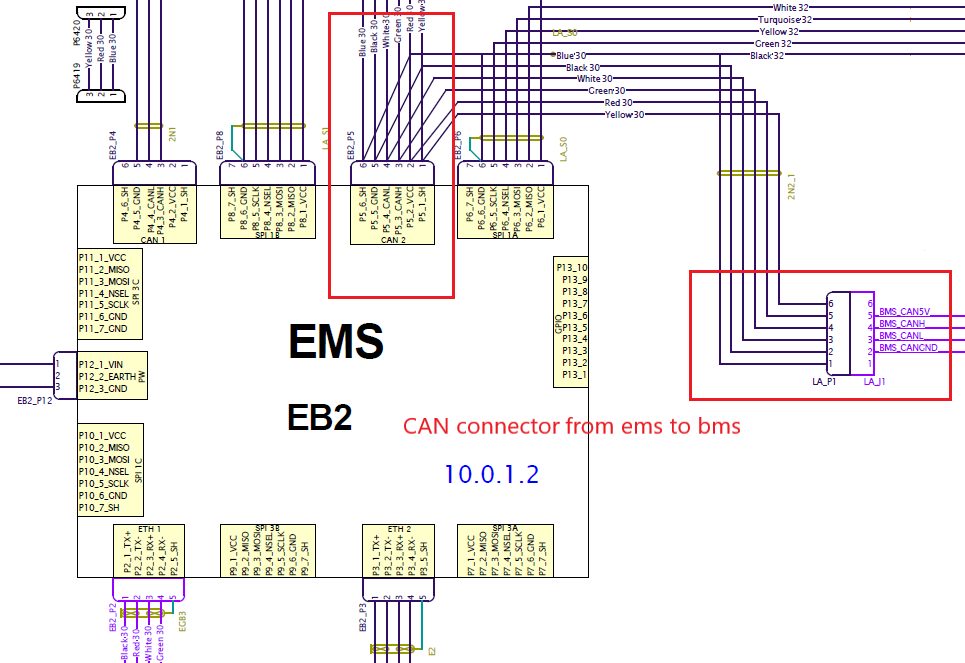

The BMS is connected to an EMS board through the CAN connector devoted to receiving the CAN frames sent out by the BMS itself. The figures below illustrate the CAN connection between the BMS and EMS boards on the ergoCub robot platform.

|

|

Output data

The BMS provides the battery pack information, such as voltage, current, state of charge, average temperature, and error flags.

Specifically, the BMS board can send the following data (which is then elaborated by fw and sw and sent to a yarp port):

- Battery-Pack Voltage in Volt. This is the

Battery packvoltage. - Total Battery-Pack Current. This is the total current, with sign, flowing outwards or inwards to the battery pack. Current has a negative sign if going out from the battery pack towards the robot and a positive sign otherwise, for example when the batteries get charged.

- Battery Pack Charge in \(\%\). This has a value different from

NaNif the robot has theBattery packswitch enabled. - Battery-Pack Temperature in \(^\circ C\). Differently from the

BATboard, this field is available forBMSand it is the average temperature of the battery pack. - Battery-Pack Status. Currently, it is a bitmask corresponding to the error flags that can be risen by the

BMS. Please see the Types of data transmitted for theBMS_STATUSmeanings.

Communication characteristics

The BMS board sends the pieces of information detailed above in polling with a frequency of 1 Hz. Then, the EMS board handles the CAN frames sent by the BAT, parses them, and finally forwards them to the higher level of the yarprobotinterface at the specific port defined in the configuration files with a default frequency of 1 Hz.

Types of data transmitted

Referring to the current CAN protocol of the BMS, the frames that the EMS manages are the following:

-

Battery pack info message sent at address

0x620as:Bytes Value Description 0-1 Battery-pack voltage in deciVolt battery pack voltage as unsigned short int 2-3 Instantaneous Current in deciAmpere battery pack instantaneous current as short int 4-5 State of Charge in % battery pack state of charge as unsigned short int 6-7 Average Temperature in Celsius batter pack average temperature as unsigned short int -

Battery pack status message sent at address

0x628in the byte0 as:Bit Value Description 0 [0 - 1] battery pack low voltage error 1 [0 - 1] battery pack high voltage error 2 [0 - 1] battery pack overcurrent in discharge 3 [0 - 1] battery pack overcurrent in charge 4 [0 - 1] battery pack low state of charge 5 [0 - 1] battery pack low temperature 6 [0 - 1] battery pack high temperature

Note

Specifically to this message, only the general alarm status of the battery pack is sent out, stored at byte 0. This identifies the single or multiple causes that trigger the alarm status on BMS. Note that, if an alarm is raised, it remains engaged for 1 minute, even if the alarm is cleared.

Data displayed on the YARP port

The user gets the data from the specific YARP port defined in the configuration file (e.g., on the ergoCub robot it is /ergocub/battery/bms/data:o). Here's the format:

- Battery-Pack Voltage, which is displayed in \(Volt [V]\).

- Instantaneous current, flowing inwards/outwards the battery pack, which is displayed in \(Ampere [A]\).

- Battery-Pack state of charge, which is displayed in \(\%\).

- Average Temperature of the battery pack, which is displayed in \(^\circ C\).

- Battery-Pack Status is displayed as a 16-bit integer (only the first 7 bits are valid), whose mapping adheres to the tables above.

Moreover, at start-up, a DEBUG message with the initial values of the status (converted to the description strings defined in the static array s_boards_map_of_battery_alarm_status in embObjBattery::updateStatusStringStream() method) is sent to yarprobotinterface.

Then, each time the status changes, a DEBUG message is sent to yarprobotinterface, which in turn prints out a description only about the values of those bits that have switched.