Motor Temperature Data Flow

Motor temperature Data Flow

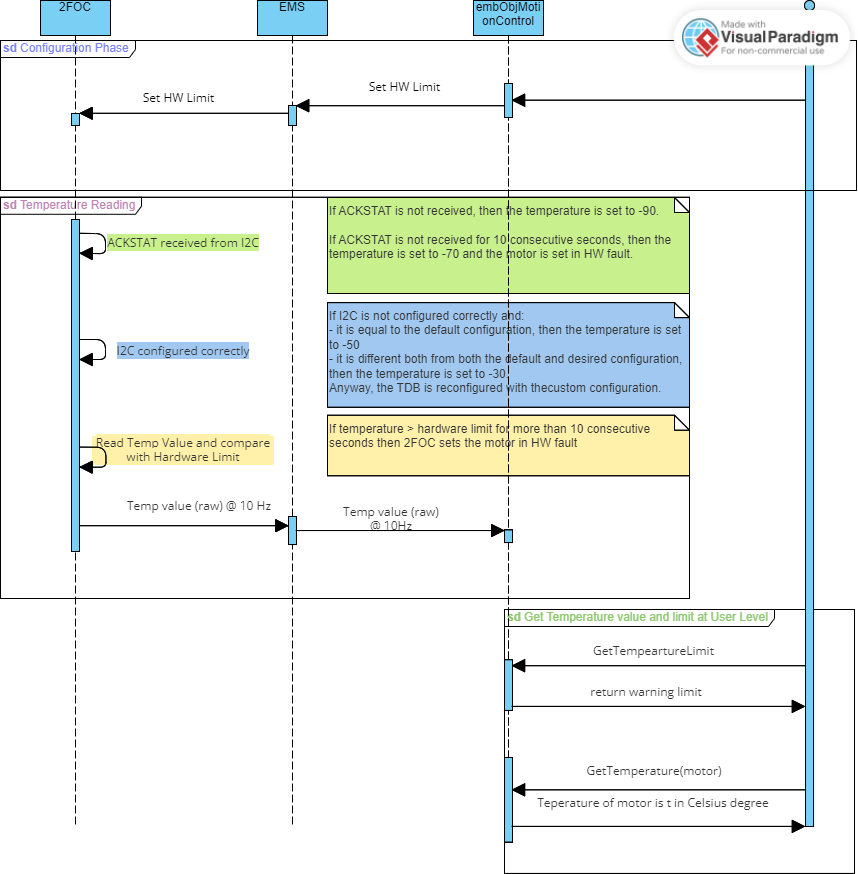

Generally, the data flow related to the whole pipeline of the sensing of the motor temperature is quite simple and a brief summary is proposed here below, whose main purpose is to make the reader aware of how the temperature data is retrieved from the motor resistance thermometer and printed out to a YARP port.

In brief, as reported in the introductory section, most of the ergoCub motors are currently provided with a PT100, which is a particular resistor able to correlate a value of temperature to a value of resistance in Ohm. The resistor is connected to a board called Temperature Detection Board (TDB).

The TBD reads the Ohm value from the PT100 (or PT1000 for different types of motors) and streams out the raw data using the I2C protocol. This raw data is then received by the 2FOC board at a frequency of 10 Hz and, immediately after, handed over to the EMS board via the CAN bus. The EMS stores the temperature values in memory and sends them to embObjMotionControl together with all the other motor information.

Upon reception of the motor temperature, embObjMotionControl converts the values from raw to Celsius and checks if the warningTemperatureLimit is overcome. In that case, it prints out a warning on the yarprobotinterface log. No other actions are taken.

Main Flow of Information

Here's a small yet exhaustive sequence diagram showing the whole dataflow as summarized above. It is possible to observe how the different actors that take part in the pipeline interact with each other, starting from the lower level up to the higher level.

Error handling

The error management is mainly performed by the 2FOC.

The 2FOC performs some checks while reading the temperature from the I2C and makes use of specific negative values (defined in the code) to notify the user of certain events.

The TDB board sends 3 bytes on the I2C bus: the temperature value (2 bytes) and its configuration (1 byte). The 2FOC verifies mainly the configuration byte.

The possible errors currently managed are the following:

-90: the2FOCcannot read from theI2C, meaning that theACKis not received from theTDB.-70: the reading cannot be done for 10 consecutive seconds. An overheating fault is triggered.-50: the TDB loses the given configuration and uses the default one. In this case, the 2FOC restores the desired configuration.-30: theTDBsets any configuration value different from both the desired and the default one.

In the logfile, the yarprobotinterface prints the raw value instead the degree Celsius. You can use the following table to understand the error.

| Degree Celsius | Raw value for PT100 | Raw value for PT1000 |

|---|---|---|

-90 |

-1141 |

-8541 |

-70 |

-886 |

-6549 |

-50 |

-631 |

-4613 |

-30 |

-378 |

-2729 |

The 2FOC triggers the Overheating error, so the motor is set in Hardware fault, when:

- it cannot read from the I2C bus longer than 10 seconds

- it reads a temperature value beyond the

hardwareTemperatureLimitslonger than 10 seconds.

The embObjMotionControl converts the received raw values to Celsius degrees and checks that the result is not beyond the warningTemperatureLimit, otherwise it prints a warning log until the temperature drops.