Fingertip skin and MMA board

Hand Sensors

Finger sensors

Tactile sensors are deployed on the fingertip. The fingertip comprises a 3DMID piece with the patterned taxels and a conventional PCB (the FT3D) reading the capacitances and hosting an IMU.

The taxel mapping is represented in Fig. 1.

Fig.1 – Taxel mapping.

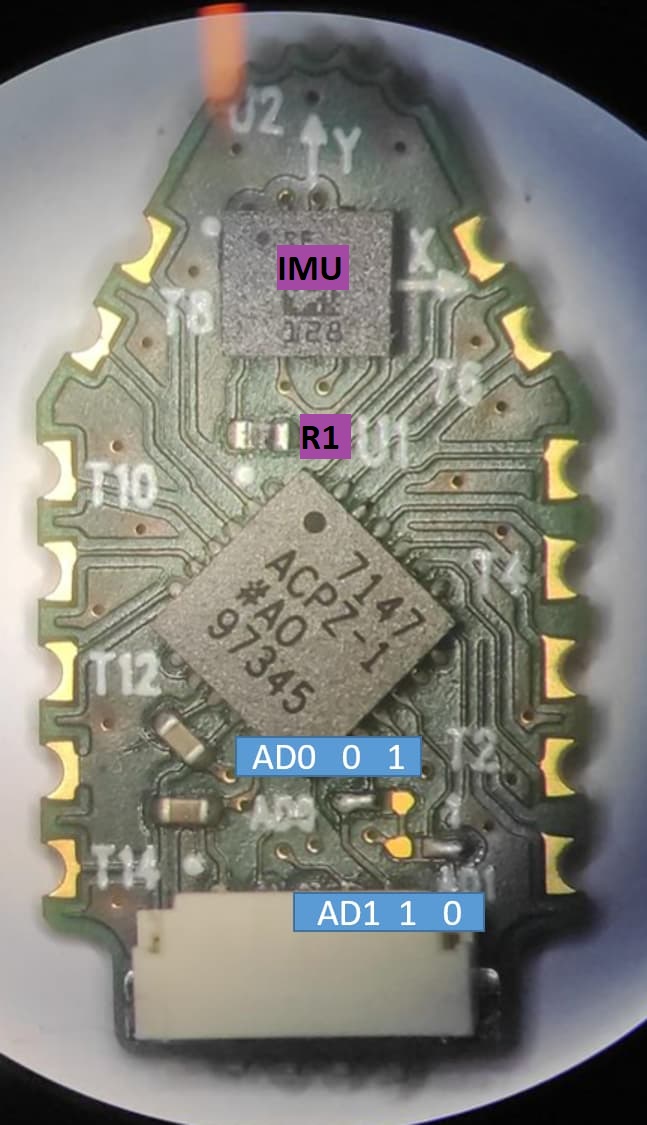

FT3D board configuration - rev. 2

The AD7147 hosted on the FT3D has configurable I2C address to allow for multiple devices.

The congfiguration is made through the jumpers AD0 and AD1 reported in Fig. 2 by simply soldering the desired connection on the dedicated jumper. Also R1 is to be removed in this revision. Depending on the connection (see below) the IMU also needs to be removed.

Fig.2 – Address configuration: the board represented has Address bits (AD0, AD1) = (0, 0).

Since the IMU is not equipped with similar configurable address pins, we need to remove all the IMUs from unwanted boards before the installation. This will be fixed in rev. 3 of the FT3D.

The complete configuration set is as follow:

ergoCub SN000

Note

In ergoCub SN000 currently the fingertips are not wired to the MMA board.

| finger | AD0 | AD1 | IMU | I2C dataline | IIT code |

|---|---|---|---|---|---|

| thumb | 0 | 0 | LSM6DSLTR | 0 | 17544 |

| index | 0 | 0 | LSM6DSLTR | 1 | 17544 |

| middle | 1 | 0 | no | 1 | 17545 |

| ring | 0 | 1 | no | 1 | 17546 |

| pink | 1 | 0 | no | 0 | 17545 |

ergoCub equipped with MMA rev. B (from ergoCub SN001)

These robots are equipped with the MMA rev. B IITCODE 16872.B

| finger | AD0 | AD1 | IMU | I2C dataline | IIT code |

|---|---|---|---|---|---|

| thumb | 0 | 0 | IIM-42652 | 0 | 15467.B |

| index | 0 | 0 | IIM-42652 | 1 | 15467.B |

| middle | 0 | 0 | IIM-42652 | 2 | 15467.B |

| ring | 0 | 0 | IIM-42652 | 3 | 15467.B |

| pink | 0 | 0 | IIM-42652 | 4 | 15467.B |

No customization of the boards is needed. They are purchased with the correct jumper configuration.

I2C dataline is decided at the MMA level through the connector assignment. The MTB to be mounted should be equipped with a dedicated firmware to enable the use of PIN 7 in the connector as an additional I2C line (SDA_4).

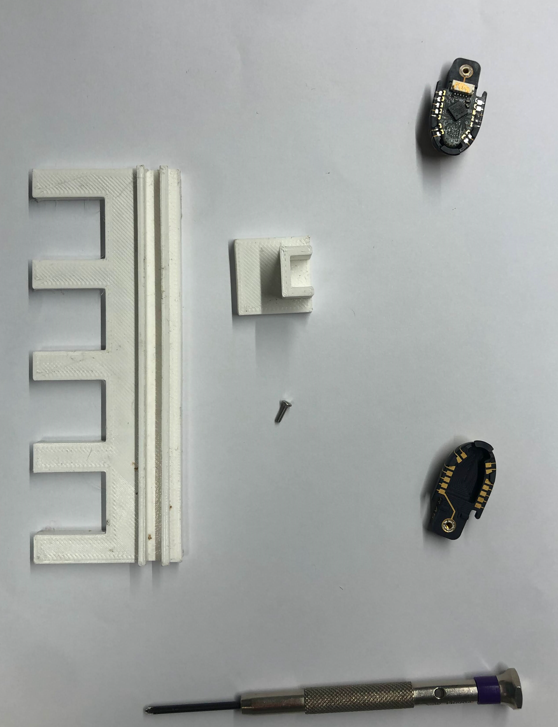

Mounting the 3DMID

Needed material (for one hand):

| IITCODE | description | quantity |

|---|---|---|

| 17628 | support for soldering | 5 |

| 17627 | base for soldering support | 1 |

| 16619 | 3DMID shells | 5 |

| 15467 | FT3D board | 5 |

| 17377 | rubber fingertip | 5 |

| 1.6x6mm screws | 5 | |

| 1.6x8mm screws | 5 |

Plus:

- low temperature solder (LTS): used Indium solder wire SMDIN52SN481

- dedicated tips for the soldering iron

- dedicated flux for LTS

- screwdriver

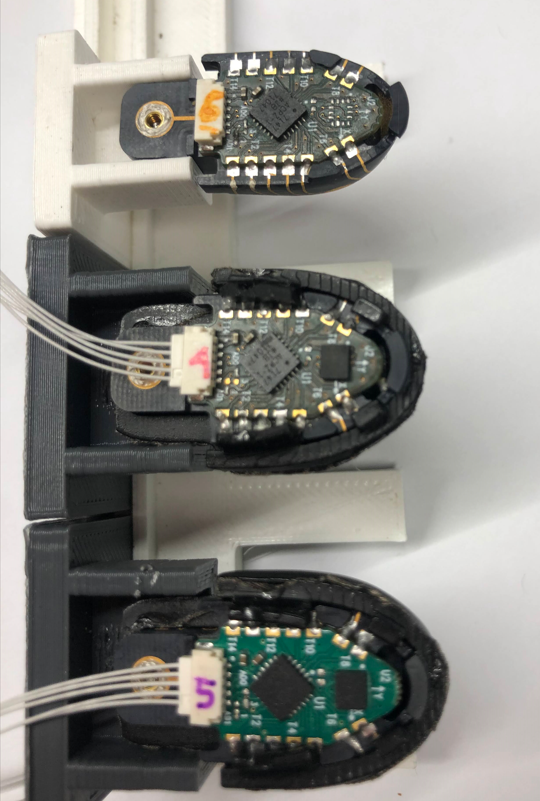

Fig.3 – Some material needed to mount the fingertips.

Procedure

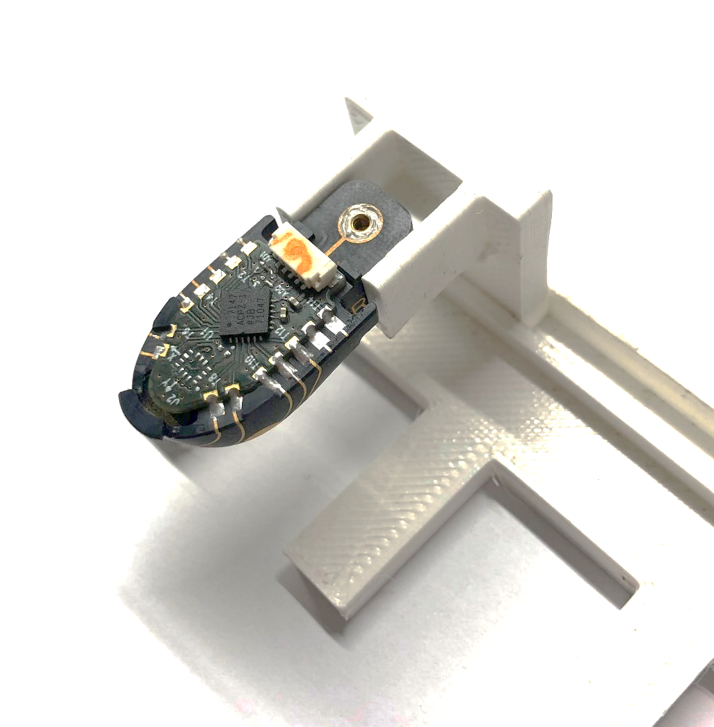

Fig.4 - fixing the 3DMID to the soldering support.

- Fix the 3DMID to the soldering support with 1.6x6mm screw.

- Plug the soldering support on the base.

Fig.5 – soldering support plugged into the base.

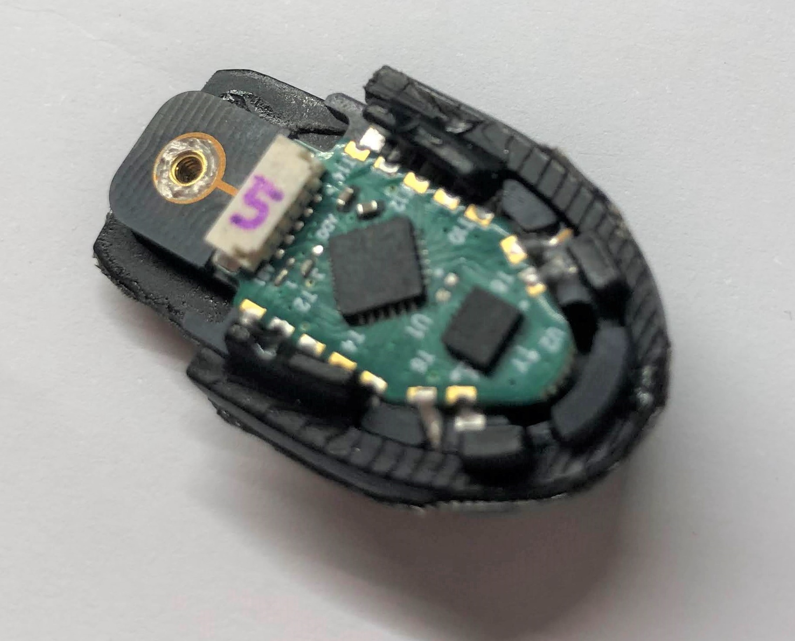

- Set the soldering iron to 250 C, apply flux and pre-tin the pads on the 3DMID.

- Apply flux and pre-tin the castellated holes on FT3DB.

- Configure the FT3DB jumpers (see section above).

- Place the FT3DB on the 3DMID aligning the soldering pads.

- Apply some flux if needed and solder a couple of pads holding the FT3DB in position.

- Go on and solder all the pads.

Fig.6 – soldered FT3DB on the 3DMID shell.

At this point the device is ready for testing, just connect it to the MMA with the dedicated cable. To fully mount the fingertip, proceed with the next steps:

- Put on the rubber fingertip cod. 17377.

Fig.7 – adjusted rubber fingertip on 3DMID shell.

- Test the fingertip in this condition.

Fig.8 – 3DMID fingertips with and without the rubber cap.

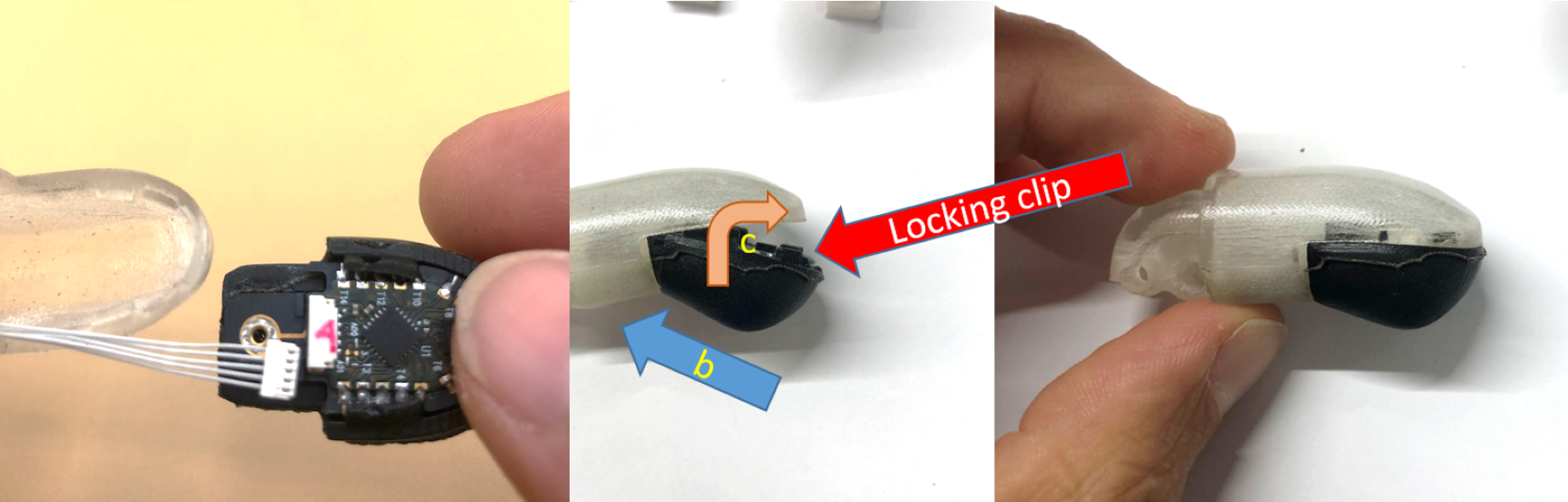

- To mount on the finger distal phalanx (fig. 9):

- Connect the cable exiting from the phalanx.

- Slide the rear of the assembly into the bore with a small inclination.

- Push up and ahead to insert the locking clip into its slot.

At this point, the assembly should look sturdy and precisely fit, in addition you can tighten it with 1.6x8 mm screw. Now it's ready for testing the signals.

Fig.9 – 3DMID fingertip insertion procedure, left: connection, center: insertion of the device, right: 3DMID device inserted into the distal phalanx.

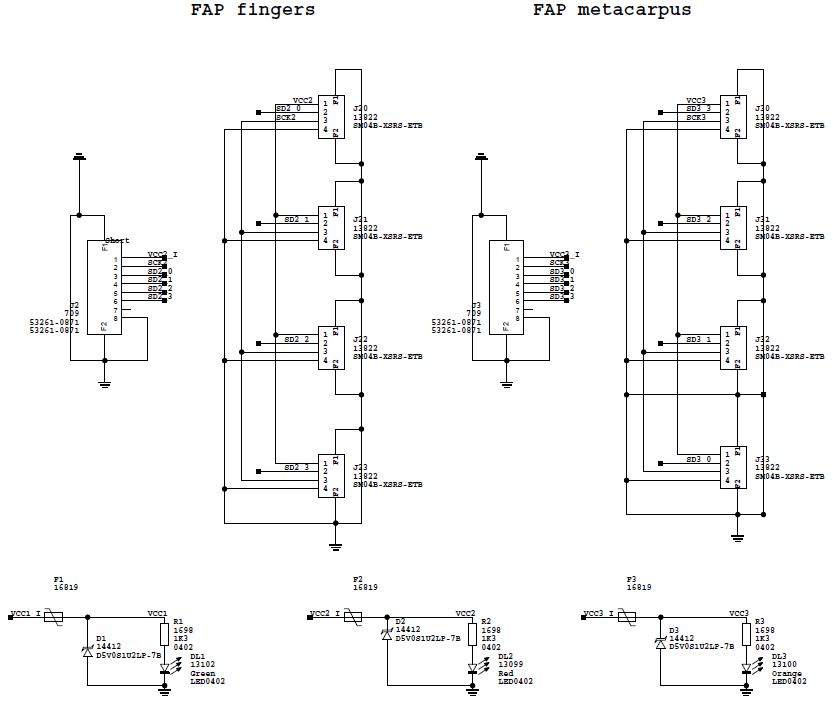

Encoders

The finger position (closing and adduction angles) are read out by a set of FAP cards (Finger Absolute Position), each one coupled with a small magnet rigidly connected to the corresponding joint. Each FAP has the same I2C address, thus one I2C data line is needed for one FAP. This is implemented at the PCB level.

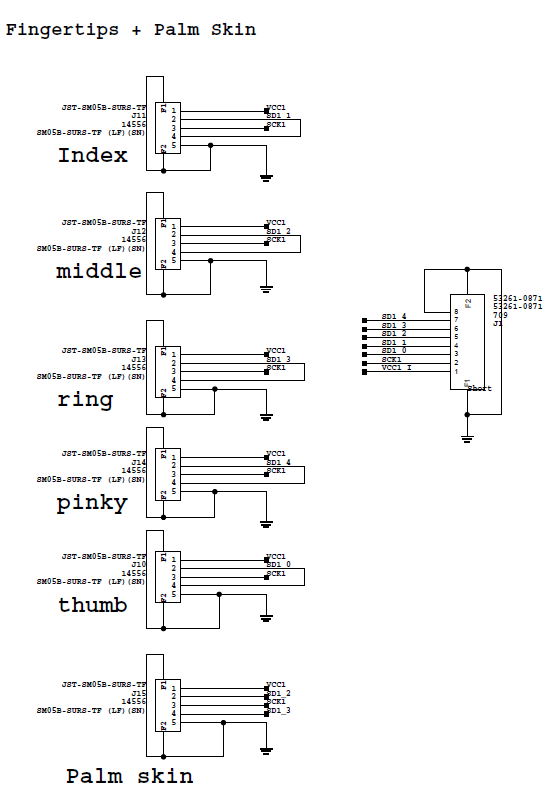

MMA Connection scheme

Three Molex 8-Pin connectors are the inputs for three dedicated MTB cards: - One MTB for tactile reading. - Two MTBs for FAP reading: max. 8 FAPs can be connected (4x MTB).

The power suppy and signals are then routed to the connectors towards the FAPs and Fingertips: - JST SURS 5 contacts for the fingertips. - JST XRS 4 contacts for the FAPs.

The family of connectors on the same device are identified with the REF DES: i.e., Picoblade J1 goes to connectors J1 1, J1 2 and so on; Picoblade J2 goes to J2 1 etc. Details are summarized in the table below:

| connector | description | sensor |

|---|---|---|

| J1 | Molex 8-Pin | conventional MTB |

| J2 | Molex 8-Pin | MTB-FAP |

| J3 | Molex 8-Pin | MTB-FAP |

| J10-J15 | JST SURS | fingertips and palm - corresponding to J1 |

| J20-J23 | JST XRS | encoders - corresponding to J2 |

| J30-J33 | JST XRS | encoders - corresponding to J3 |

The encoders are connected with the following logic: - Finger position encoders are to be routed to one MTB-FAP. - Adduction encoders are to be routed to the other MTB-FAP.

The connection of the MTB-FAP can be made allowing for the simplest layout and reported here and in the wiring scheme.

The schematic of the MMA is shown below.

Tactile sensors

Fig.3 – Skin connections. The fingers belonging to the same Data Line can be swapped.

The tactile sensors are connected to the MMA as in Fig. 3. The fingers (index, middle, ring) can be swapped to account for easier cabling, with no effect in mapping of the signals. Also, Thumb and Pink can be swapped the similarly.

Encoder connection

The encoders are connected as reported in the table above and in the schematic snapshot in Fig. 4.

Fig.4 – FAPs connections. The FAP mapping should be reported in the configuration files for proper working of the joints.

Software items

To use correctly the data from the sensors we need to have the following information embedded in the configuration files.

Signal wrapping in configuration files

For the configuration of the Wrapper file in the robots-configuration tree, for streaming through the YARP services and signal visualization, the mapping of the signals is reported in the table below:

ergoCub SN000 & SN001

| Finger | board nr. | Taxel Index |

|---|---|---|

| Thumb | 4 | 48-59 |

| Index | 0 | 0-11 |

| Middle | 1 | 12-23 |

| Ring | 2 | 24-35 |

| Pink | 5 | 60-71 |

| Palm | TBD | TBD |

ergoCub with MMA rev.B

| Finger | board nr. | Taxel Index |

|---|---|---|

| Thumb | 0 | 0-11 |

| Index | 4 | 48-59 |

| Middle | 8 | 96-107 |

| Ring | 12 | 144-155 |

| Pink | 16 | 192-203 |

| Palm | TBD | TBD |

AD7147 configuration

The values for the mk2 fingertip are reported here, to be implemented in .xml files with the proper labeling:

| Parameter | Value |

|---|---|

| Bitshift | 2 |

| CDC offset | 0x0000 |

| No load value | note2 |

Encoders mapping in the configuration files

🚧 WIP 🚧

-

See link or buy from usual suppliers of electronics goods. ↩

-

The No load value can be choosen to be lower than 0xF0 (240) to allow for some room for opposite polarity signals to be recorded. In this case, the set level must be forwarded to high level tools such as SkinGUI etc. for a proper managing of events. A nice choice could be a value of about 0xC0 (192) to have ~60 ADC counts of headroom for opposite sign forces, i.e., shear forces, to be measured with the lateral taxels or elastic effects for non-touched taxels to improve force measurement. ↩